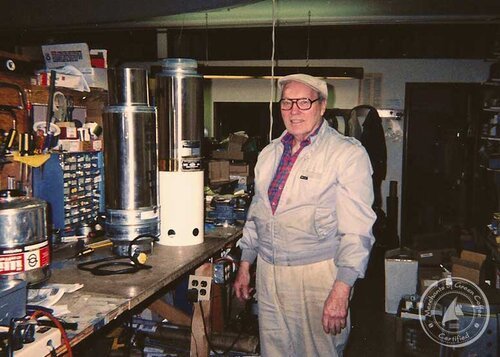

Introducing the SRM15

The SRM15 builds upon the robust reputation of the original Sivetz design by modernizing control features to meet a new echelon of coffee roasters. The result is a completely stainless steel, handmade fluid bed roaster that gives you direct control over your coffee’s development.

A Case for Convection

The Sivetz SRM15 is a fluid bed roaster, meaning the coffee beans float on a bed of hot air during the roasting process. Built on Michael Sivetz’s original patent from 1976, this allows convective heat transfer and airflow to be the sole variables, providing a gentle and effective heating environment for the coffee. Comparatively, the metal in a drum roaster transfers heat to the surface of the coffee bean 1000 times faster than air, leading to scorching and uneven development.

SRM15 Features

Controls

Directly Control Development

The Sivetz SRM15 air roaster controls the roast by inlet temperature rather than gas modulation and incorporates a variable speed fan for maximum air control. This affords direct and precise control of the coffee as it roasts, as opposed to using gas modulation to heat a drum on a standard drum roaster.

Productivity

Increase Productivity up to 2x

Utilizing a fluid bed of hot air, you can achieve light to medium roasts in 7-9 minutes without scorching, yielding highly consistent and thorough inner bean development. This means back-to-back roasting can yield 200 lbs/hr at full capacity (15k). 7-9 minute roasts using a drum roaster lead to scorching and lower inner bean development.

Profiling

Original Fluid Bed, Reimagined

Among the updates to the original Sivetz air roaster design, the SRM15 boasts profile roasting, allowing you to repeatedly finesse the heat application and fan speed to bring out the most prized flavor profile and aromatics from your coffee. Profiles can be saved and even automated.

Batch Versatility from 7.5k to 15k

Due to the fluid bed design and thermodynamics of convective heat, the Sivetz SRM15 roaster is highly versatile, capable of roasting as little as 9 kilos, all the way up to max capacity at 15 kilos. Unlike most roasters that require users to roast a full batch at ~70-80% capacity (in part due to the lower efficiency of drum roasters), the SRM15 can handle a full batch at 100% capacity.

Why Choose Fluid Bed Air Roasting?

Less Variables

Less Variables During Roasting

Directly controlling inlet temperature means that you aren’t reliant on a modulated gas flame to steer the roast temperature. This means SRM15 warm-up time is about 5 minutes, compared to 30-45 minutes on a drum roaster. SRM15 between batch protocol (BBP) is around 1 minute, compared to ~10 minutes for drum roasters.

Consistency

Less Impact from Seasonality

Due to the power and effectiveness of the SRM15’s fluid bed, air roasting environment, variances in ambient room temperature have far less of an impact, giving you consistency in any season. This also means that between batch protocol (BBP) and the “flick” are less impactful, since the SRM15 provides more power and control.

Pure Development

Consistent, Clean Roasting

Bring out the delicious sensory characteristics of your coffee without imparting off-flavors from inconsistent heat application. High air flow provides an environment for even heat distribution and removes chaff quickly. Convective air roasting is typically characterized by a cleaner cup profile.