IT/BT Profiling: what is it, and what are the advantages?

Are you looking to improve roast consistency and repeatability?

One of the most significant upgrades we made when redesigning the SRM15 was the ability to modulate the gas and fan speed. This opened the door to A) roasting different batch sizes, and B) creating multi-step recipes to profile a certain bean. In this article we will focus on B).

The recipe is a way for the roastmaster to apply different amounts of heat during different phases of the roast, and then save it for infinite repeatability.

In this blog, we want to focus on which method we have chosen, and how this provides a production roaster both flexibility and repeatability.

Why we chose Inlet Temperature (IT) to control the roast

Most recipe systems currently offered (air and drum) are based on burner % or time, neither of which accurately measures the actual conditions inside the roast chamber.

Burner % - The conditions that result from setting a burner at x % will fluctuate based on changes in ambient conditions. Consider how we cook food: when baking a cake in the oven, we don’t set it at x % gas or power, we tell it to bake at 425 degrees. You want to control the actual temperature rather than the conditions that would lead to a similar temperature.

Time - Making changes to the Inlet Temp based on time does not take into account what is actually happening in the roaster. Fluctuating ambient conditions and other variables will result in inconsistent results when following a timed schedule.

Our recipe system is based on IT/BT profiling: changes throughout the roast are being made to the Inlet Temp (IT) based on targets being reached by the Bean Temp (BT).

In this blog post, Scott Rao explains why IT/BT profiling with air roasting leads to more consistent results.

“I cannot overstate the superiority of controlling roasts by inlet temperature rather than valve settings.”

“The beans do not experience the gas-valve settings, they experience the inlet temperatures produced by those settings. However, since ambient air is drawn through the burner, unless the ambient temperature is tightly controlled, a given valve setting will produce different inlet air temperatures as ambient conditions change.”

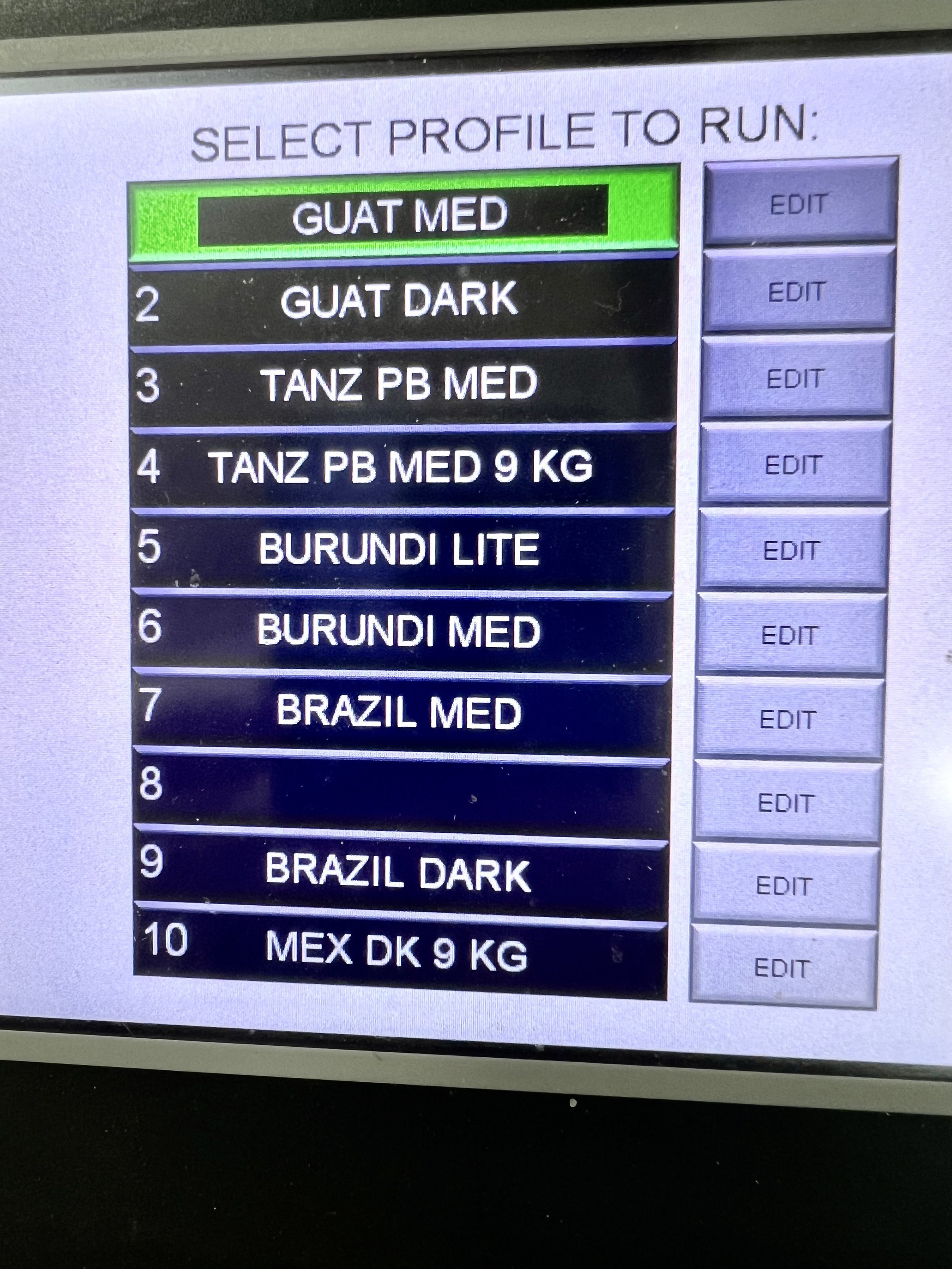

When roasting beans with recipes on the SRM15, you are modulating the Inlet Temp (based on targets reached by Bean Temp) through multiple stages of the roast (up to 12).

Once a recipe has been crafted, it can be saved and then repeated.

You have the freedom to create a precise, targeted approach to each bean variety, and then the ability to have a junior roaster repeat that recipe again and again to ensure repeatability and consistency.

Shann Bosnell from Brown Bag Coffee Roasters in Gatineau, Quebec says, “When it was time for us to upgrade our roaster, and stay within the air roasting world we looked at all the players. After conversations with Michael and seeing demo roasts remotely, we were convinced the Sivetz approach to using IT/BT coupled with on-device profiling meant we could accomplish more roasting per hour, consistently. Fast-forward 6 months into using the roaster and it has more than exceeded what our expectations are. Feedback from our customers has been overwhelmingly positive on our coffee coming out of the machine. Simple, straightforward maintenance also makes it easy for my team to ensure our roaster is working at peak efficiency. I would not hesitate to recommend a Sivetz SRM15 to anyone looking at stepping up their roasting game with high-quality, repeatable profile roasting.”

Combining this precise approach to roasting with the benefits of convective air roasting leads to the ever-elusive win-win scenario: roasting more coffee, with more precision, while experiencing fewer roast defects and using fewer resources.

Aided by a separate fan and motor to independently cool the beans, a single roaster can roast 5 to 6 full batches per hour (75 to 90kg). Click here to view a one-minute time-lapse video of 90kg being roasted by Shann in 65 minutes.